EPDM roof repair is a critical task for property managers who oversee buildings with this durable yet specialized roofing material. While EPDM (ethylene propylene diene monomer) roofing is known for its longevity and resilience, like any roofing surface, it can develop issues over time that require attention. Addressing roof problems early can save you time, money, and headaches in the long run.

This guide will walk you through:

- The most common problems faced by EPDM roofing.

- Step-by-step solutions for fixing these issues.

- Why investing in professional roofing expertise is essential.

Understanding how to care for your rubber roof ensures you can maintain the integrity of your property while increasing its value.

What is EPDM Roofing?

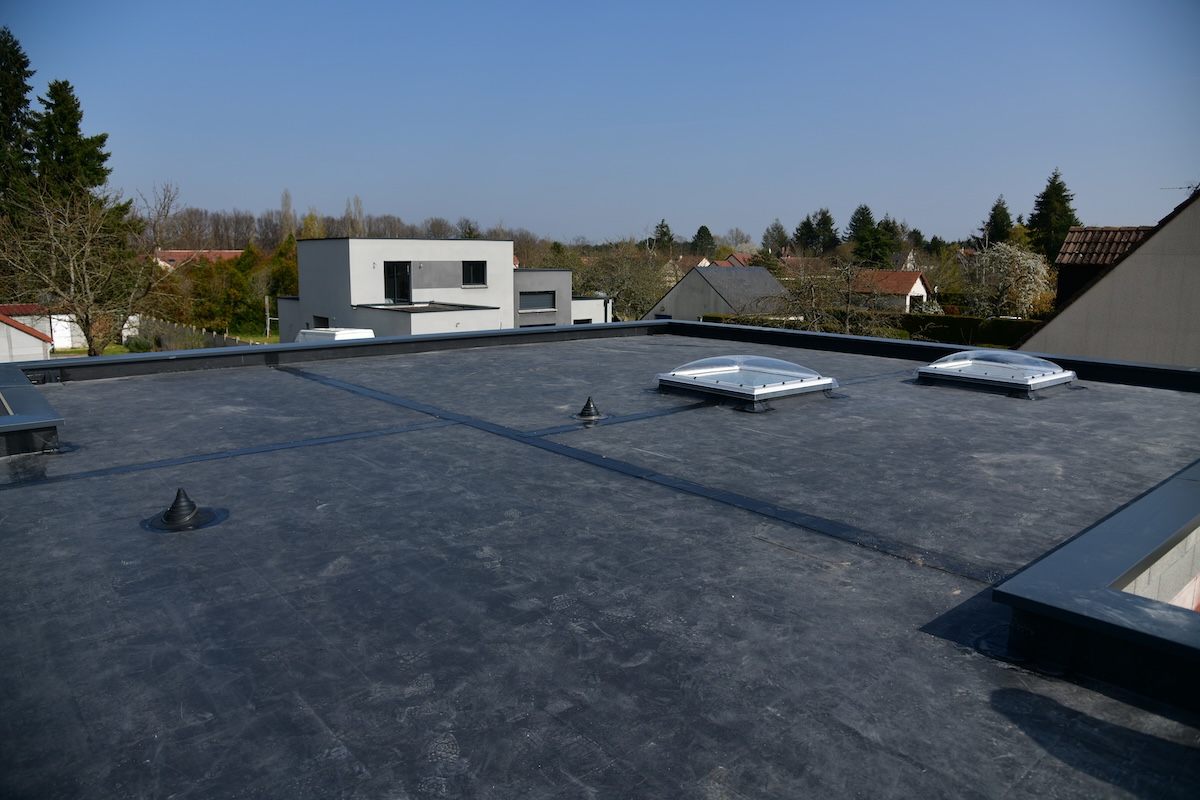

Before discussing repairs, it’s important to understand what EPDM roofing is. EPDM is a synthetic rubber membrane widely used on flat or low-slope roofs. Its benefits include exceptional durability, resistance to extreme weather, and a lifespan ranging from 25 to 30 years when well-maintained. However, its performance depends on proper installation and timely repairs.

Here’s an in-depth look at the common EPDM problems you might encounter and the steps to fix them.

❌ Common Problems with EPDM Roofs

While EPDM roofing is built to last, property managers may notice a few recurring issues. Below, we’ll cover the most common problems affecting EPDM roofs.

1. Roof Membrane Punctures or Tears

Causes: Foot traffic, falling debris, or poorly installed equipment can create small punctures or tears in the membrane. Over time, these can grow into larger problems, leaving the roofing surface vulnerable to leaks.

Solutions:

- Inspection: Conduct regular inspections to identify even the smallest rips.

- Patch Repair: Use an EPDM-compatible patching material, which includes a primer and adhesive, to seal the damaged area. Ensure the patch fully covers the puncture to prevent further leaks.

- Preventative Measures: Where heavy foot traffic is unavoidable, consider installing walkway pads to protect the membrane.

2. Shrinkage of the EPDM Membrane

Causes: Over time, EPDM may shrink due to weather exposure or aging adhesives. Shrinkage can cause stress on flashings and seams, potentially leading to cracks.

Solutions:

- Re-adhesion: If edges are pulling away, clean the affected area, apply a bonding adhesive, and reseal.

- Professional Assessment: If shrinkage is widespread, consult a professional roofer to evaluate whether a partial replacement or extensive repair is necessary.

- Routine Maintenance: Routine flat roof inspections can help identify shrinkage before it becomes problematic.

3. Issues with Seams and Flashing

Causes: The seams and flashing on your rubber roof are vulnerable to wear and tear or improper sealing during installation. Temperature fluctuations can also stress these areas, causing separations.

Solutions:

- Resealing: Clean the affected seams, apply a fresh EPDM seam primer, and use seam tape designed for rubber roofs.

- Professional Seam Repair: For extensive seam failures, professional assistance will ensure a watertight fix.

- Regular Monitoring: Frequent inspections of seams and flashing can extend their lifespan and reduce overall repair costs.

✅ Step-by-Step EPDM Roof Repair Process

Not all EPDM roof repairs require the same approach. Below, we’ll discuss a step-by-step process for handling some of these issues practically.

- Clean the Area: Thoroughly clean the area surrounding the damage using a manufacturer-approved cleaner. Ensure no dirt, grease, or debris is left, as these can prevent proper adhesion of patches or sealant.

- Cut and Apply the Patch: Cut an EPDM-compatible patch to size, ensuring it extends at least 2 inches beyond the damaged area on all sides. Apply adhesive to both the patch and the roofing surface, allowing a few minutes for it to become tacky before firmly pressing the patch into place.

- Use a Roller for a Firm Seal: To enhance adhesion, roll the patch firmly using a weighted roller. Ensure every edge is securely sealed to prevent water from getting underneath.

- Inspect and Apply Seam Tape (if necessary): For repairs involving seams, clean the seam, apply seam primer, and use a high-quality seam tape for a watertight finish. Roll over the tape to ensure proper adhesion.

- Conduct a Final Inspection: After completing the repair, inspect the area thoroughly to confirm all edges are sealed and the repair looks seamless. This final step is crucial to avoid recurring leaks or other damage as well as the overall energy efficiency of your roofing system.

☎️ When to Call an Expert

While many EPDM roof repairs can be handled with basic tools and materials, some situations warrant professional help. These include:

- Widespread or extensive membrane shrinkage.

- Severe damage to the flat roofing surface or insulation.

- Persistent leaks that don’t resolve with patching or seam repairs.

Professional roofers have the experience, tools, and expertise to address complex problems, ensuring that your rubber roof remains in top condition for years to come.

👍 Why Choose G. Cannon for Your EPDM Roof Repairs?

Entrusting your EPDM roof repair to a seasoned professional isn’t just a smart decision; it’s an investment in the longevity and durability of your property. At G. Cannon, we understand the challenges property managers face when maintaining EPDM roofing. That’s why we’re the team you can count on to deliver exceptional service, quality craftsmanship, and expert solutions.

Here’s what you can expect when you choose G. Cannon:

- Expertise You Can Trust: With years of experience in EPDM roof repair, no problem is too big or small for our skilled team.

- Tailor-Made Solutions: We know every property is unique, so we provide personalized repair strategies to match your roofing needs.

- Dependable Quality: Using only the highest quality materials and state-of-the-art techniques, we ensure repairs are built to last.

- Customer-First Approach: Your satisfaction is our priority. We’re committed to keeping you informed and empowered throughout the repair process.

Is your property’s EPDM roof showing signs of damage? Don’t wait for small issues to turn into major headaches.

Contact G. Cannon today to keep your rubber roof in perfect shape. Whether it’s a simple fix or complex repair, our team is here to help you safeguard your investment.